DIVIDO Line

The DIVIDO Line from SATTRI is excellent for working with multifilament fibers. These cutting-edge systems are adaptable, well-proven, and field-tested, and are capable of producing high-quality technical multifilaments. The quality of the finished product and energy efficiency are ensured through distinguishing features to meet your needs.

Polyester, Polyamide, Polyolefin, Polyethylene, Biomaterials, and Bi-Component polymers can all be processed with the DIVIDO Line. It is possible to make a large number of filament cross sections. The equipment is set up in accordance with the filament specifications. Versions with High Tension are available.

So what can we offer you?

- Machines, completely built and tested at our location.

- Plug and play concept, only connection of utilities required for start-up.

- Extensive sets of processing parameters already programmed for all processes and polymers.

- Robust industrial components designed for 24/24, 7/7 applications.

- Easy shipping because the machines fit into standard container sizes without the need for disassembly.

- Economical and flexible system by using only the necessary units:

- With or without the DIVIDO Premo (extrusion-spinning) unit.

- Possibility to add additional units later.

- Possibility to add additional units later.

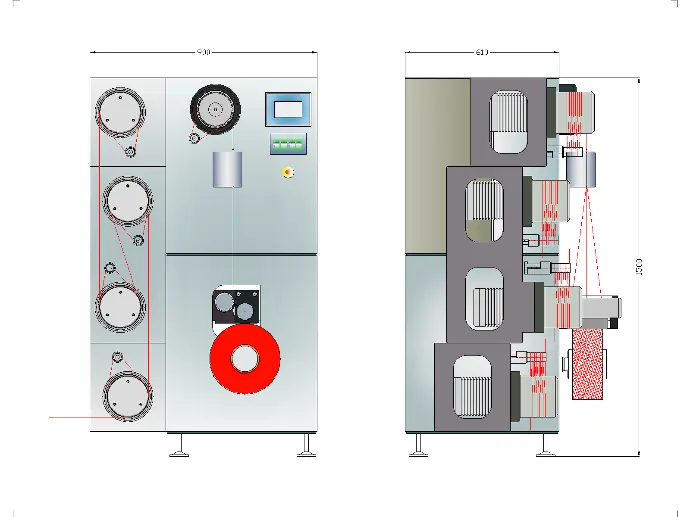

Extrusion Modules

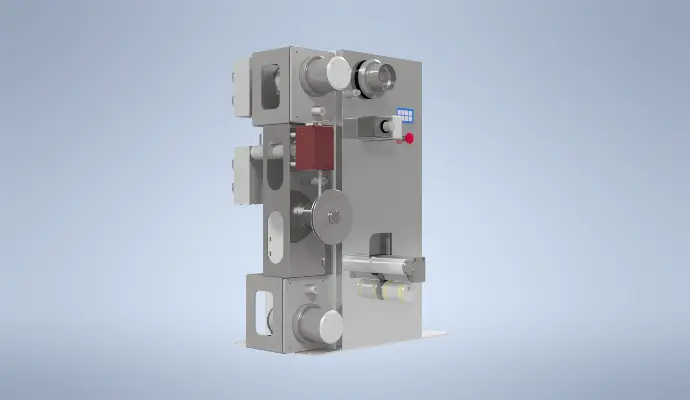

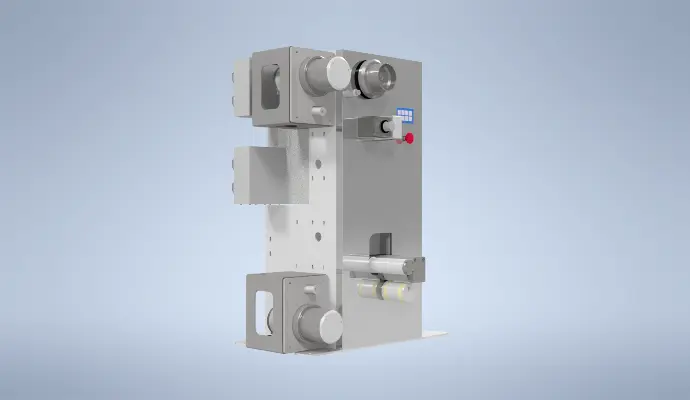

DIVIDO Premo

With Meltpipe

Stand-alone unit for extrusion spinning. Power supply 400VAC 3Ph 32A. Air pressure 7 bar 0.3m³ / min. Chilled water supply (8-12 ° C) 15lt./min.

Take-up Modules

DIVIDO BCF

Stand-alone unit for BCF production. Power supply 400VAC 3Ph 25A. Air pressure 7 Bar 2.1³ / min.

DIVIDO POY-FDY

Stand-alone unit for POY-FDY production. Power supply 400VAC 3Ph 20A. Air pressure 7 Bar 1.0³ / min.

DIVIDO POY

Stand-alone unit for POY production.

Power supply 230VAC 1Ph 20A air pressure 6 Bar 0.3³ / min.

DIVIDO HT

Stand-alone unit for High Tenacity production.